blown film machine pdf

Air ring exit air volume on output. Blown film air cooling Vol.

How To Make An Interesting Art Piece Using Tree Branches Ehow Edible Oil Cooking Oil Rice Bran Oil

They gain an overview of the configuration and working principle of the machine and learn to understand the functionality and technical processes of the individual stations.

. We are producing blown film lines since 1967 and have consistently set new standards such as the development of the internal bubble cooling system and the oscillating haul-off. Several billion pounds of polymer mostly polyethylene are processed annually by this technique 1. Blown film is a major processing technique for producing a biaxial melt drawn film.

Machine Construction A cut-away drawing of a simple single screw machine is shown in Figure 1. LDPELLDPE ABA Die and Air Ring. Material Reduce film COF add slip Process Keep film tension between 1 and 25 of ultimate tensile strength Equipment Repair worn haul-off nips slippage Realign die idlers cage collapsing frame Replace dull slitting blades Clean dirty rollers Eliminate web tension pulsations Edge Variation.

Many types of polymers are extruded into blown film but various grades of polyethylene comprise the vast majority. DESCRIPTION OF THE BLOWN FILM EXTRUSION PROCESS. Blown Film Lines for Higher Output Other machine options.

This paper describes the blown film extrusion pro- cess presents the dynamic equations for Pearson- Petrie model discusses some steady-state results ob- tained from the dynamic model at long times and examines the dynamic response of the model to both startup and various process disturbances. Gravimetric blender dosing system. Motorized openclose updown Bubble Cage.

Coextrusion of blown film Coextrusion is the extrusion of multiple layers of material simultaneously. Oxygen in the feed throat hopper is a major issue for blown film extruders as it causes carbonization on the screw and dyes. It is our hope that this work will serve as a training resource for all levels of professional and operations personnel working in the plastics film industry including.

Additives are used in most operations to provide performance appearance or cost benefits. The tubular blown film process is efficient and economical and can produce a magnifi- cent array of products from a light gauge clear converter film to heavy gauge construction film which when slit and opened may measure 40 feet or more in width. 11 Polymers For any product it is the desired property set that determines the best material for the application.

Blown Film Machine HIGH SPEED TWIN DIE BLOWN FILM MACHINE Features. Our blown film portfolio offers the right machine for your individual production needs. The bottleneck in blown film extrusion lies in the cooling of the fast moving thin melt film It is important to understand that three elements of the blown film process are of first order importance to be able to produce near uniform gauge blown.

Groove Feed Barrel and cooling jacket available. The participants become familiarized with the machine operation. Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5 μm according to Butler 1.

The blown film extrusion process can produce magnificent arrays of products however. Plastic film manufacturing con-. Blown Film Machine CE45-65TT CE55-75TT Features.

Many types of polymers are extruded into blown film but various grades of polyethylene comprise the vast majority. Blown Film extrusion technology for packagingconvertingagrifilm Flat Die extrusion technology for the production of rigid thin films and thick sheets Bandera history now 198090 196070 1950 1947 1943 33. This type of extrusion utilizes two or more extruders to melt and deliver a steady volumetric throughput of different viscous plastics to a single extrusion head die which extrude the materials in the desired form.

High quality mixing in screw and barrel delivers excellent homogeneity and high output. This technique uses air pressure to produce a transverse direction draw and a higher speed haul-off roll speed to provide a machine direction draw. In blown tubular film much controversy exists concerning the effect of air ring exit air velocity vs.

Description This course qualifies the participants for the daily work with WH blown film extrusion lines. We have tried to add new technology and organize the previous material into an effective format. Given therefore a single screw machine is being described that has a screw of diameter 60 mm and a length of 24 screw diameters that is a LD ratio of 241.

Constant film tension windup system For either single-station windup or two-station windup A sensor detects the film roll diameter and adjusts the torque drive accordingly Film windup tension is constant at all roll diameters Roll diameter up to a maximum of 600 mm. Processing our understanding of the extrusion of tubular blown film remains in the stage of art. Parker Hannifin Corporation Industrial Gas Filtration and Generation Division 4087 Walden Ave.

Chiller and Chill Air Box for Air Ring. At extrusion it forms a liquid tube which is simultaneously drawn in the vertical direction by nip rolls inflated by an internal pressure and cooled by external air rings. 51 Introduction to Blown Film Extrusion.

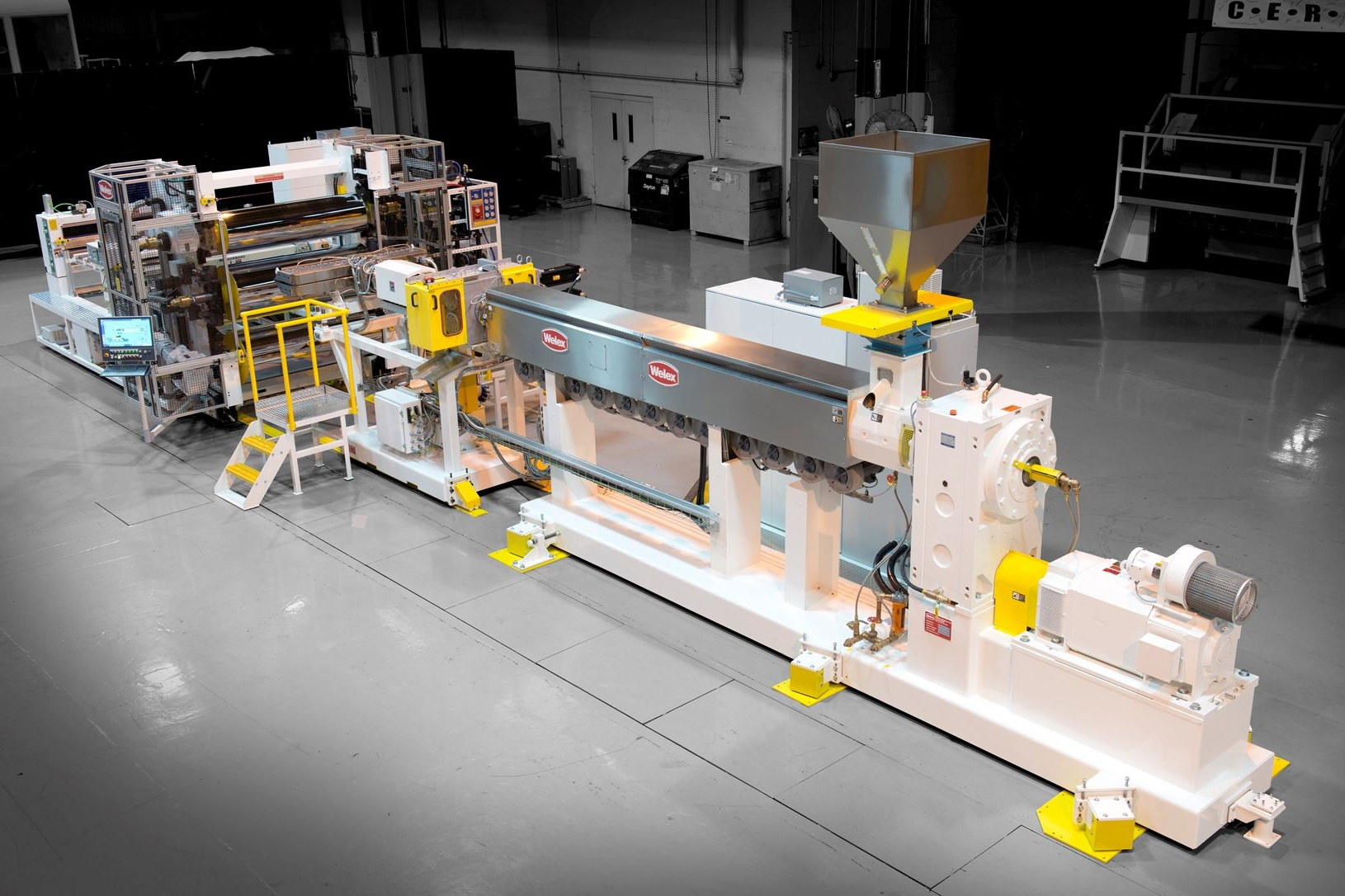

Melt pressure Gauge. WH blown film lines are designed especially for the flexible packaging industry. Basic Blown Film Line Figure 1 Elements of Blown Film Figure 2 3 Main Arena of Action.

This shows the arrangement of the different parts of the machine. High performance main motor AC inverter drive designed for energy saving and minimum maintenance. 11 Polymers The desired property set for any product determines the best material for the applica- tion.

Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5 μm according. Nip inverter motor is designed for accuracy and reliability. Working of Blown Film Extrusion Machine Units Components Purpose Pallet feeding unit Material conditioner.

The polymer is melted in an extruder and the hot melt is pumped through a die to form a thin-walled tube which is simultaneously axially drawn and radially expanded. Blown film extrusion is one of the most commonly used thin gauge fabrication processes for manufacturing plastic films in the world. Bandera currently managed by Franco and Piero the founders sons has recently focused its product range on two main technologies.

Manual screen changer. Additives are used in most operations to provide performance appearance or cost benefits. 8 3 December 1979 Question No2 reads as follows.

There is one camp which promotes high air velocities as the key to bubble stability and output.

Feed Screw Manufacturing Rebuilding And Design For Plastic Injection Molding Extrusion Blo Recycling Machines Plastic Injection Plastic Injection Molding

Plastic Bags Arabian Line Plastic Dubai Printed Bag Printed Bags Zipper Bags Plastic Bag

Pin By Desi Boy Challenge Sharma On Goutam Plastic Design Extrusion Sorting Trash

Manufacturer Sale Rice Bran Oil Extraction Plant Machine Mill Projects Solution Rice Bran Oil Oils Cooking Oil

Instant Download Vintage Crochet Pattern For Milk Jug Cover Sugar Bowl Cover Pdf Email Delivery Vintage Crochet Vintage Crochet Pattern Crochet Patterns

Articulated Sw At St Lego Star Wars Lego Star Star Wars Figures

The 90 Best Gadgets Of The 90s Cool Gadgets Answering Machine 90s

Ocp Ed 209 3d Obj Voennye Transportnye Sredstva Modeli Transportnoe Sredstvo

Blown Film An Overview Sciencedirect Topics

Cartoning Machine Designed For Egyptian Customers Factory Design Machine Design Packing Machine

Solving Gels In Thin Film Tubing Extrusion Plastics Technology

The Upper World By Femi Fadugba In 2021 World Thriller Femi

Film Blowing Machine Xydc 1000 Film Blowing Machine Garbage Bag Making Machine Automatic Star Sealing Bag Making Machine Hi Making Machine Film Bag Making

Blown Film An Overview Sciencedirect Topics

Wpc Extrusion Wood Plastic Composite Machine Wpc Profile Extrusion Line Pvc Wood Plastic Machine Wpc Profile Producti Wood Plastic Composite Extrusion Wood

Shj 72 Twin Screw Compounding Extruder For Pp Pe 50 Calcium Carbonate Structure Design Screw Design

Yellow And Black Love Joy Peace Design Hand Painted Mouth Blown Glass Hanging Christmas Ornament Christmas Ornaments Handpainted Christmas Ornaments Yellow Ornaments

Those Magnificent Men In Their Flying Machines Music Memories Digital Sheet Music Sheet Music